Kanban System Inventory Management

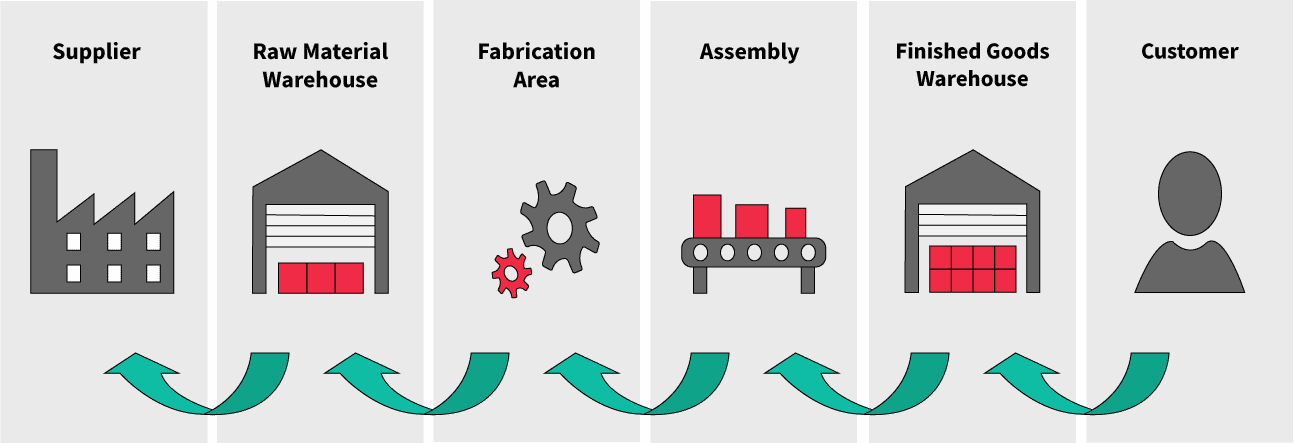

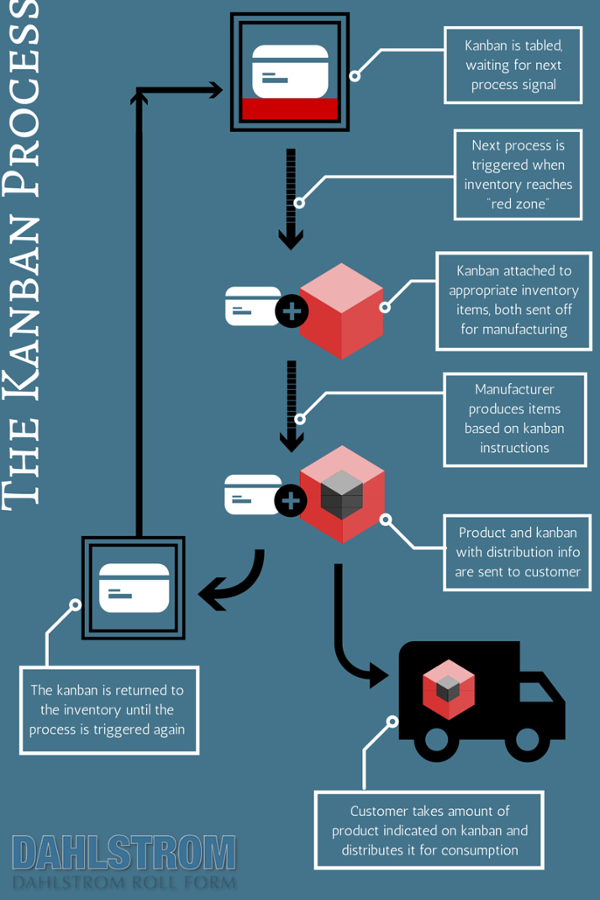

Kanban system inventory management. The objective of the Kanban inventory management system is to effectively eliminate supply usage forecasting in manufacturing processes. GetApp has the Systems you need to stay ahead of the competition. The main idea behind the Kanban system is to deliver what the process needs exactly when it needs it.

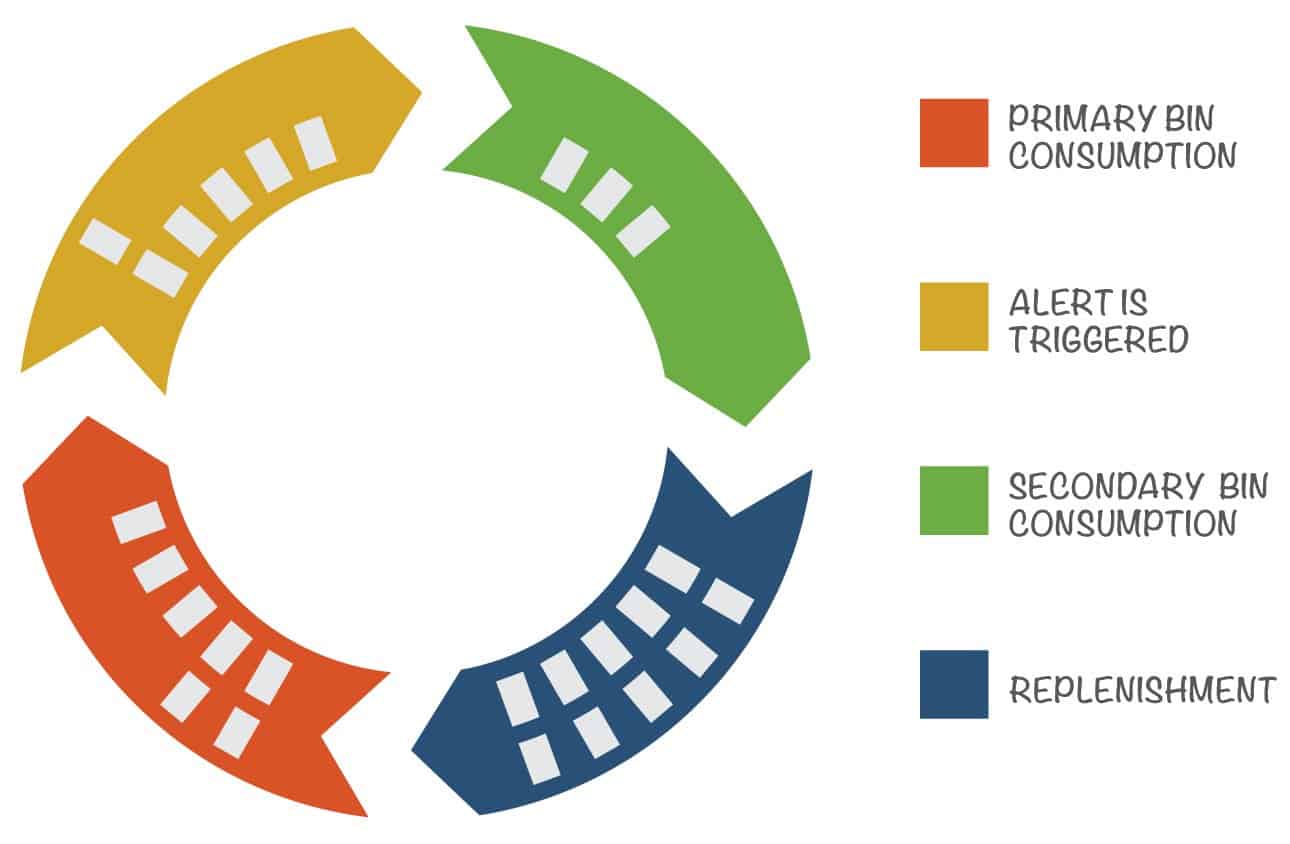

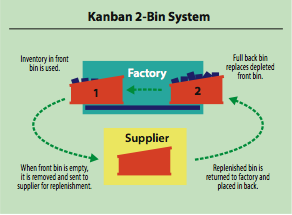

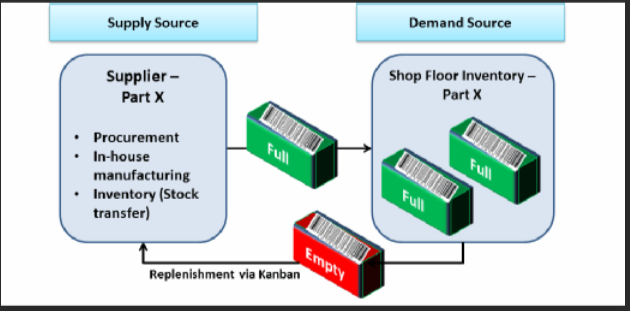

In a nutshell a Kanban inventory system aligns inventory levels with actual consumption rather than stocking items and then expecting them to sell. That is the goal of a Lean process. Kanban inventory management is an elegant solution to managing and tracking workflow.

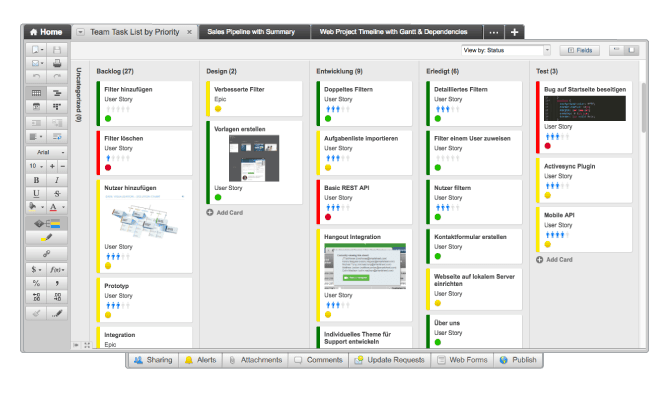

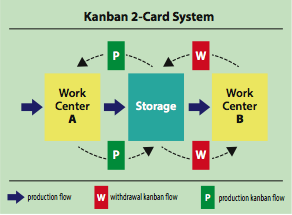

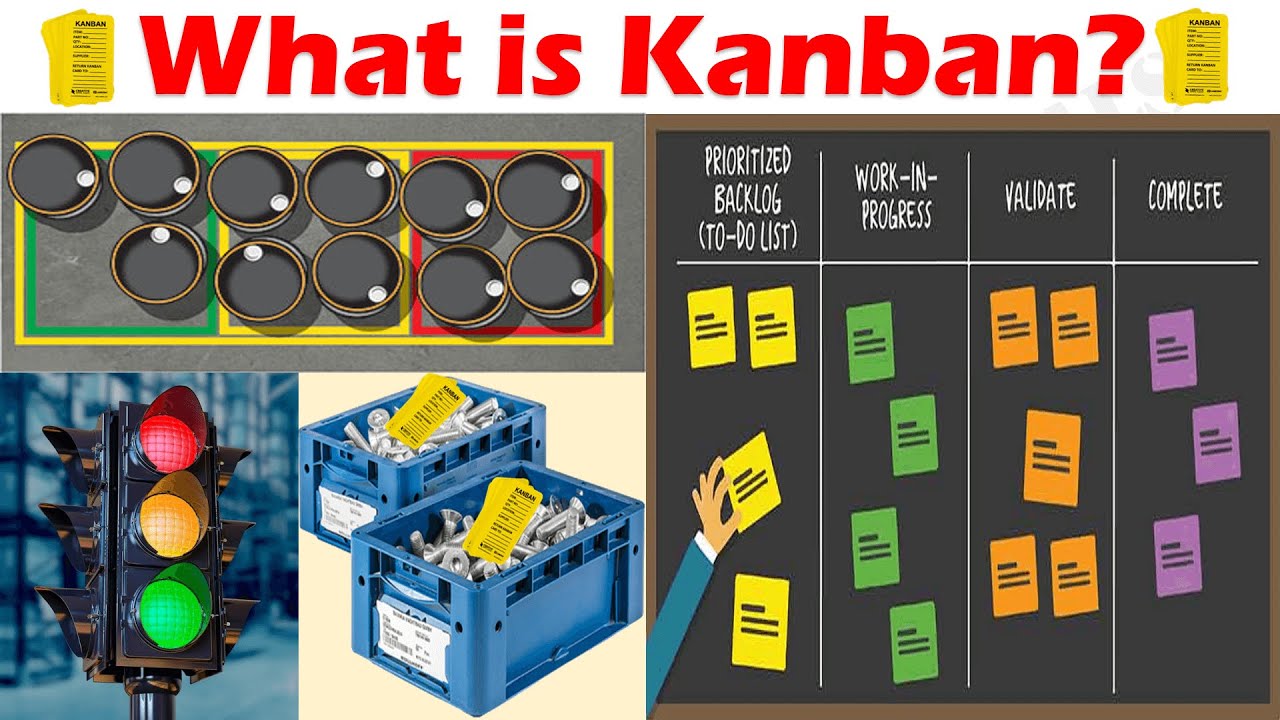

It simply optimizes the process flow. Gerencie projetos ágeis de forma colaborativa e visual. In Japanese the word Kan means visual and ban means card so Kanban refers to visual cards.

Kanban Inventory Management. Kanban was originally developed at Toyota in the1950s as a way to manage material flow on the assembly line. A kanban inventory management system provides a straightforward graphic chart of the thing you need when you really need it plus where.

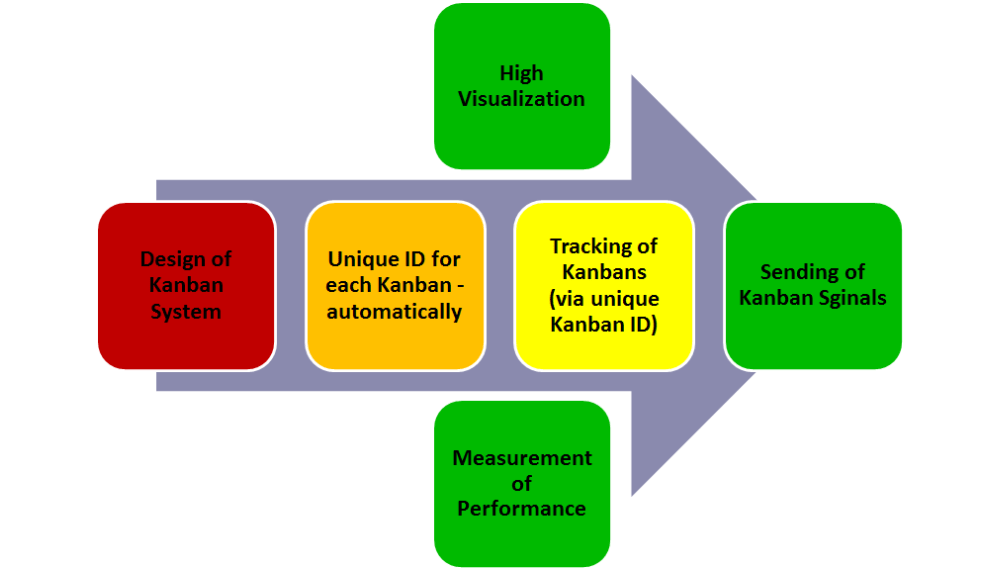

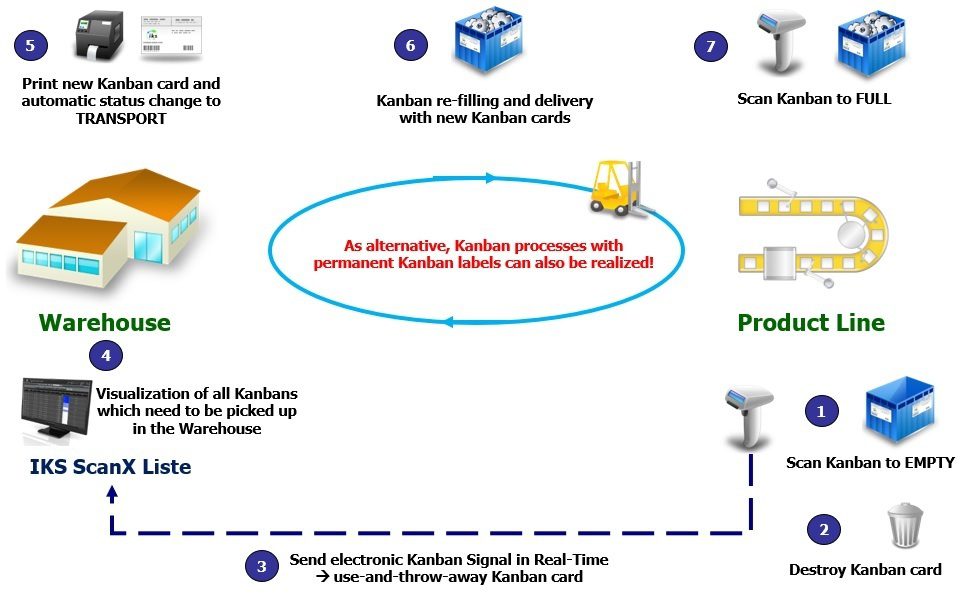

Sensitive points Implementing a proper Kanban system comes with a certain set of rules without which Kanban can quickly become inefficient or void of meaning. Kanban e quadros completos. Kanban a technique for work and inventory release is a major component of Just-in-Time JIT and Lean Manufacturing philosophy.

Kanban e quadros completos. Limits on the number of items waiting at supply points are established and then reduced as inefficiencies are identified and removed. Inventory management is a science primarily about specifying.

Ad See the Inventory Systems your competitors are already using - Start Now. It was created as a simple planning system the aim of which was to control and manage work and inventory at every stage of production optimally.

Hence proving to be like a.

Sensitive points Implementing a proper Kanban system comes with a certain set of rules without which Kanban can quickly become inefficient or void of meaning. Sensitive points Implementing a proper Kanban system comes with a certain set of rules without which Kanban can quickly become inefficient or void of meaning. A goal of the kanban system is to limit the buildup of excess inventory at any point in production. Inventory management is a science primarily about specifying. Kanban system controls the entire chain from suppliers to the end-sellers. Hence proving to be like a. Kanban e quadros completos. There are numerous strategies for implementing the Kanban system within an organization. The first Kanban system was developed by Taiichi OhnoIndustrial Engineer and Businessman for Toyota automotive in Japan.

As a consequence implementing Kanban usually leads to inventory reductions and therefore costs reduction storage space gains dead stock reduction etc. Over the last three decades the Kanban processa highly efficient and effective factory production. You may then line up this together with your strategic business plan to ensure each side tend to be practical. Kanban e quadros completos. Whenever a limit is exceeded this. Ad Gerencie os projetos da sua empresa com uma ferramenta simples e eficiente. Kanban is Japanese for card or visual signal.

Post a Comment for "Kanban System Inventory Management"