Water Jacket Cooling System

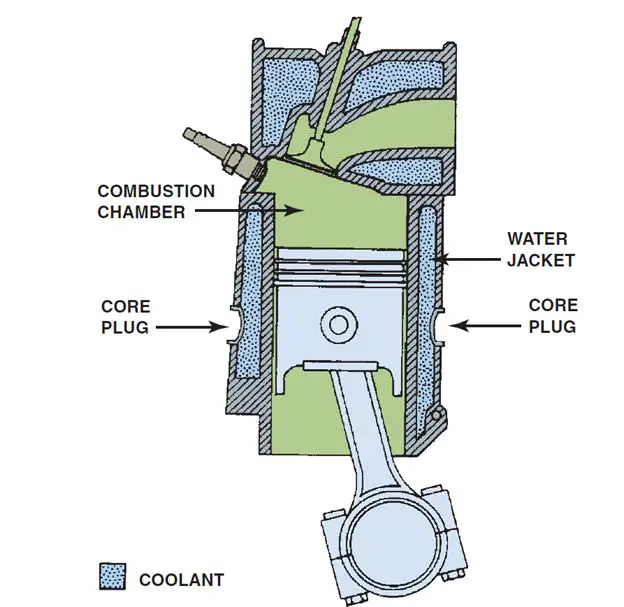

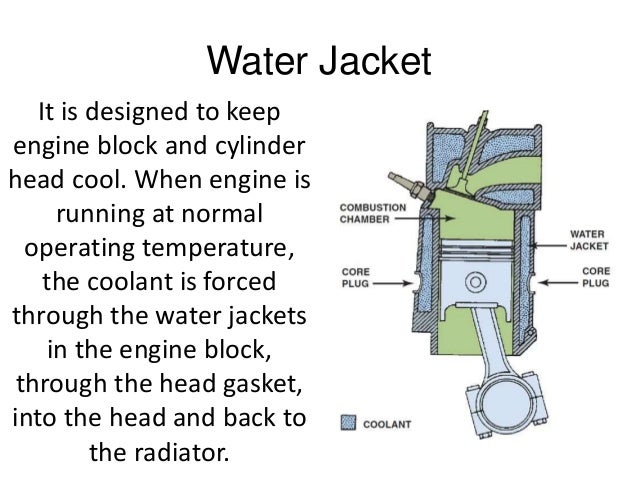

Water jacket cooling system. The passages of the water jacket are designed to control circulation of coolant and provide proper cooling throughout the engine. The forced circulation type water cooling system uses a water pump to pressurize the cooling liquid of the system to flow in the water jacket. Cooling water jackets are provided around the cylinder cylinder head valve seats etc.

In order to fulfill the technical requirements of a high-efficiency low-emissions off-road horizontal diesel engine a unique design is proposed and optimized in this paper for the cooling water jacket structure with a forced-cooling closed-loop cooling system. In this there is a hopper on a jacket containing water which surrounds the engine cylinder. Cooling Water System Components.

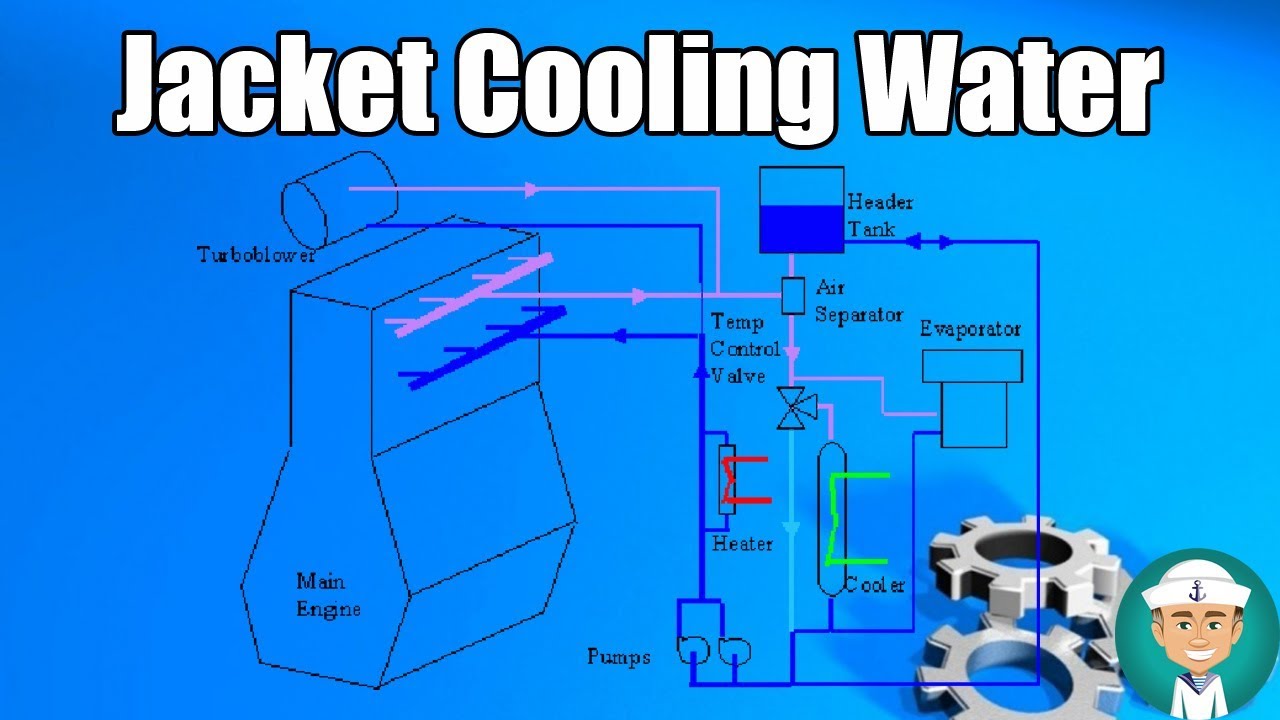

24 Cooling architectures. A flow of relatively cooler gas through the cylinder and jacket cooling that prevents the temperatures of rubbing surfaces from rising too high. The jacket water keepwarm system is shown along with the normal jacket water cooling system on the same schematic in Figure 61.

The cylinder jacket cooling water after leaving the engine passes to a sea-water- circulated cooler and then into the jacket-water circulating pumps. The flow of water to an external heating or cooling device allows precise temperature control of the device. The tall water jacket works as a manifold flowing high-velocity water for cooling and adding to the structural robustness in the head to handle the higher firing pressures.

A water jacket is a water-filled casing surrounding a device typically a metal sheath having intake and outlet vents to allow water to be pumped through and circulated. The expansion tank maintains the static pressure in the cylinder cooling water system and replaces the lost water. A header tank allows for expansion and water make-up in the system.

A cooling water pump is required to. This is not to say that each component is at its normal temperature. At the same time the motor is predestined for extreme installation locations as dirty aggressive and salt-laden air is.

Due to the powerful blowing action of the fan the air flows through. An engine fitted with this system cannot run for several hours without it being.

A cooling water pump is required to.

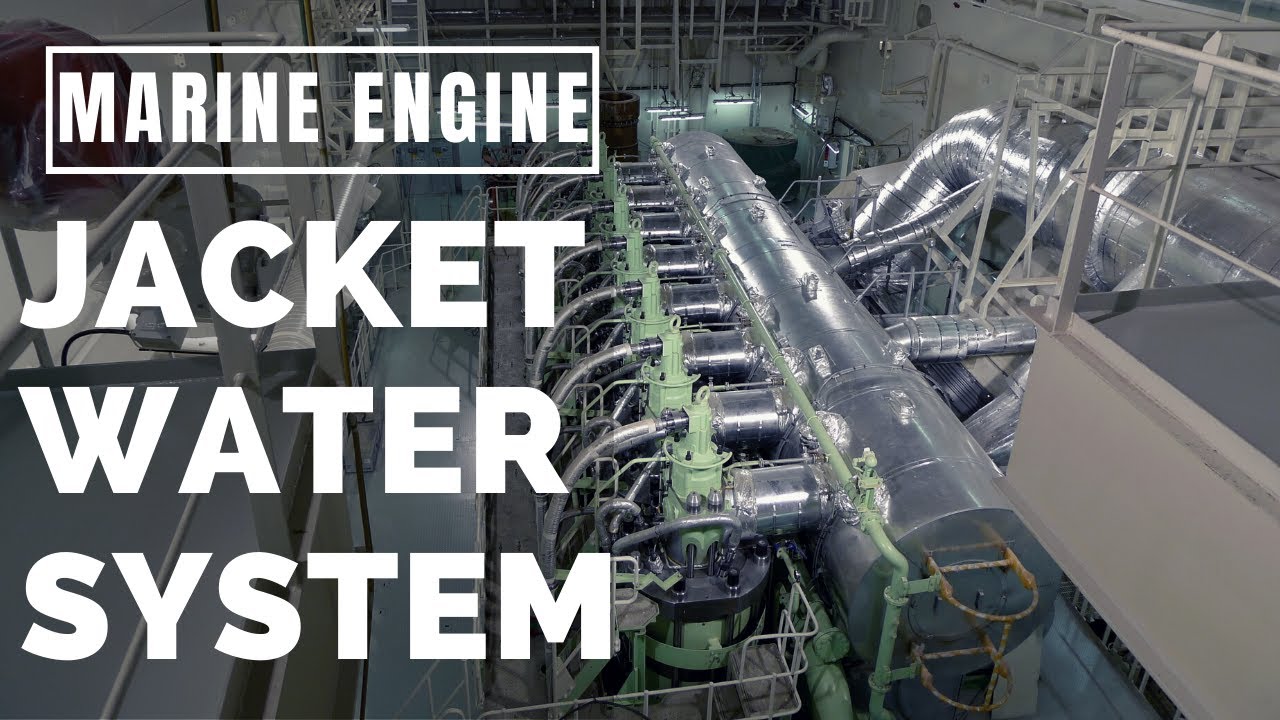

This is not to say that each component is at its normal temperature. Jacket Cooling Water System. Engine Cooling Water System. Liquid Cooling For high power density machines air cooling is not enough and liquid cooling is needed Liquid is generally either water or oil Two main topologies. The tall water jacket works as a manifold flowing high-velocity water for cooling and adding to the structural robustness in the head to handle the higher firing pressures. It is then pumped around the cylinder jackets cylinder headsand turbo-blowers. The water is supplied by an external system and enters the motor through the connections on the motor end bell drive end or non drive end. A header tank allows for expansion and watermake-up in the system. The circulating water in these jackets absorbs the heat from the cylinder surface and then heated water is cooled by the air passing in the radiator.

This system functions to keep the overall temperature of the engine coolant at or near its normal operating temperature. A header tank allows for expansion and watermake-up in the system. The jacket cooling water system is used for cooling the cylinder liners cylinder covers and exhaust valves of the main engine. The water is supplied by an external system and enters the motor through the connections on the motor end bell drive end or non drive end. The pump forces coolant directly from the lower radiator tank connection into the forward portion of the cylinder block. An engine fitted with this system cannot run for several hours without it being. Water jacketing that allows the existence of a high viscosity lubricating oil film on the cylinder wall to reduce friction and wear.

_1.png)

Post a Comment for "Water Jacket Cooling System"